Hydraulic Elevator

It is the elevator design where the drive capability is provided by the hydraulic pump unit. These are the systems in which the hydraulic oil is transmitted to the lifting pistons by a pump and the cabin is moved directly or indirectly by the pistons. Downward movements are realized by the own weight of the cabin. Hydraulic elevator is the first choice in elevator design without elevator machine room, such as residential, hospital and villa. Hydraulic elevators are more cost-effective and space-saving where mechanical energy is obtained through fluid. We guarantee the best service for hydraulic elevators that stand out with their comfort, ease of control and vibration-free. Hydraulic elevators are often preferred because they transmit electricity easily and therefore consume less power and energy. It can be designed for both passenger and freight, and in hydraulic elevators, the load of the elevator is supported by the building. Another reason why hydraulic elevators are preferred is that they provide safety without the need to go down the well or go upstairs in an emergency. The hydraulic fluid is supplied by the elevator and directly or indirectly affects the elevator to the passenger cabin. This downward movement of the elevator car is provided by its own weight.

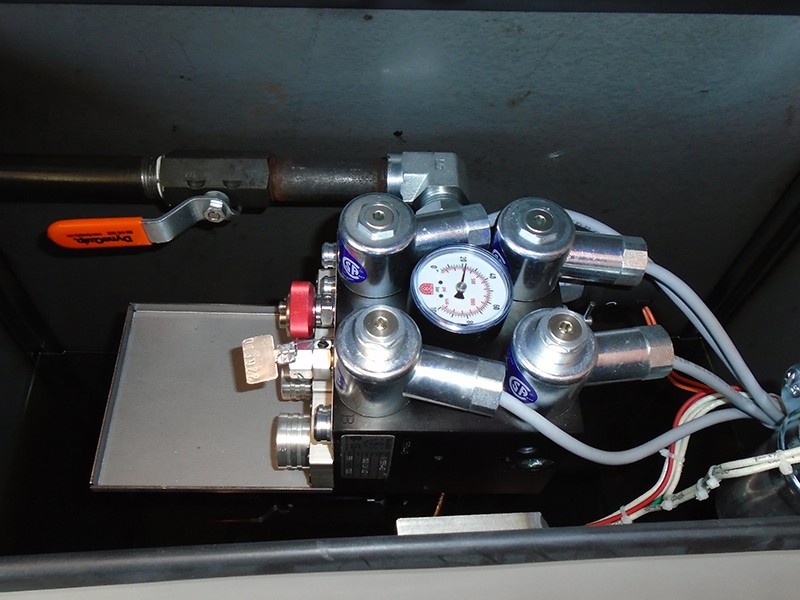

The cabin hydraulic lift is usually located at the first floor level. This is where the control panel is placed on the hoses and hydraulic oil by means of an oil-fired boiler and hydraulic press assembly. In elevator shafts; cabin counterweight, cylinder-piston system, suspension elements and bumpers. Hydraulic elevators are electric oil pumps that work by pushing a piston into the foundation of the elevator car. Meeting the specific requirements of a hydraulic press, the pump oil drives the cylinder along the pipeline.